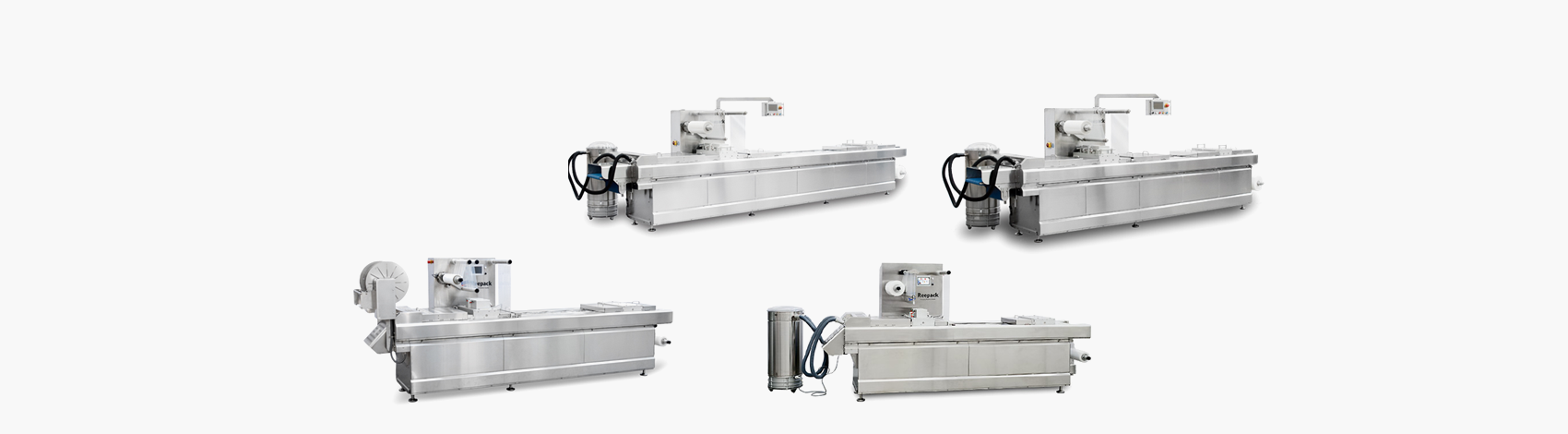

ReeForm E10

Small and capable, the E10 is the most compact model in Reepack’s latest generation line-up.

It is ideal for processing all types of sliced products in shallow packs and also prepared foods or medical products in deeper packs with or with out modified atmosphere using flexible films. With fixed machine frame dimensions the E-10 provides 2-3 loading stations with speeds of 4-8 cycles per minute.

A wide number of sealing and cutting options are possible for ideal product presentation.

ReeForm E40

The E-40 is a compact and reliable latest generation machine with standard formats and a powerful range of forming possibilities.

This comprehensive machine meets a wide range of product demands through a variety of package options from shallow to deeper formats with or without MAP. The E40 effectively produces different package types from vacuum shapes or skin packs to high definition trays all suitable for high-quality product presentations.

The E-40 provides 4-5 loading stations with speeds of 5-10 cycles per minute. Flexible or semi-rigid film applications can be processed using vacuum forming, preheating, and plug-assist options.

A wide number of sealing and cutting options are possible.

ReeForm T45

The T45 is a versatile medium to large scale production machine with full customization possibilities.

This high-performance machine can be precisely configured to your product and package requirements in shallow to extra deep (150mm) with or without MAP. The T45 effectively produces packages from flexible and semi-rigid shapes and formats to VSP skin-packs with forming up to perfectly rigid trays.

The T45 modular frame enables a variable number of loading positions following customer cut-off requirements and the expansion flexibility to integrate easily with peripheral equipment and automated packaging lines.

This machine processes at speeds of 8-12 cycles per minute and makes full use of complete forming technology systems including vacuum forming, preheating, and plug-assist options.

A wide number of sealing options make it possible to produce any type of final presentation package.

ReeForm T55

With maximum performance and capability, the T-55 is Reepack’s largest full scale production thermoforming machine.

The T55 machine is designed for high output industrial requirements. It offers the broadest range of configuration and size possibilities to meet any product and package demand. The T55 produces flexible vacuum formats, semi-rigid trays and shapes, VSP skin-packs as well as perfectly formed rigid trays.

The T55’s wider frame enables larger sizes or added format quantities. The modular basis of this machine enables a customizable number of loading positions following customer cut-off requirements with the flexibility of expansion to integrate easily into automated packaging lines.

The T55 processes at speeds of 8-12 cycles per minute and makes full use complete forming technology systems including vacuum forming, preheating, and plug-assist options.

A wide number of sealing options make it possible to produce any type of final presentation package.