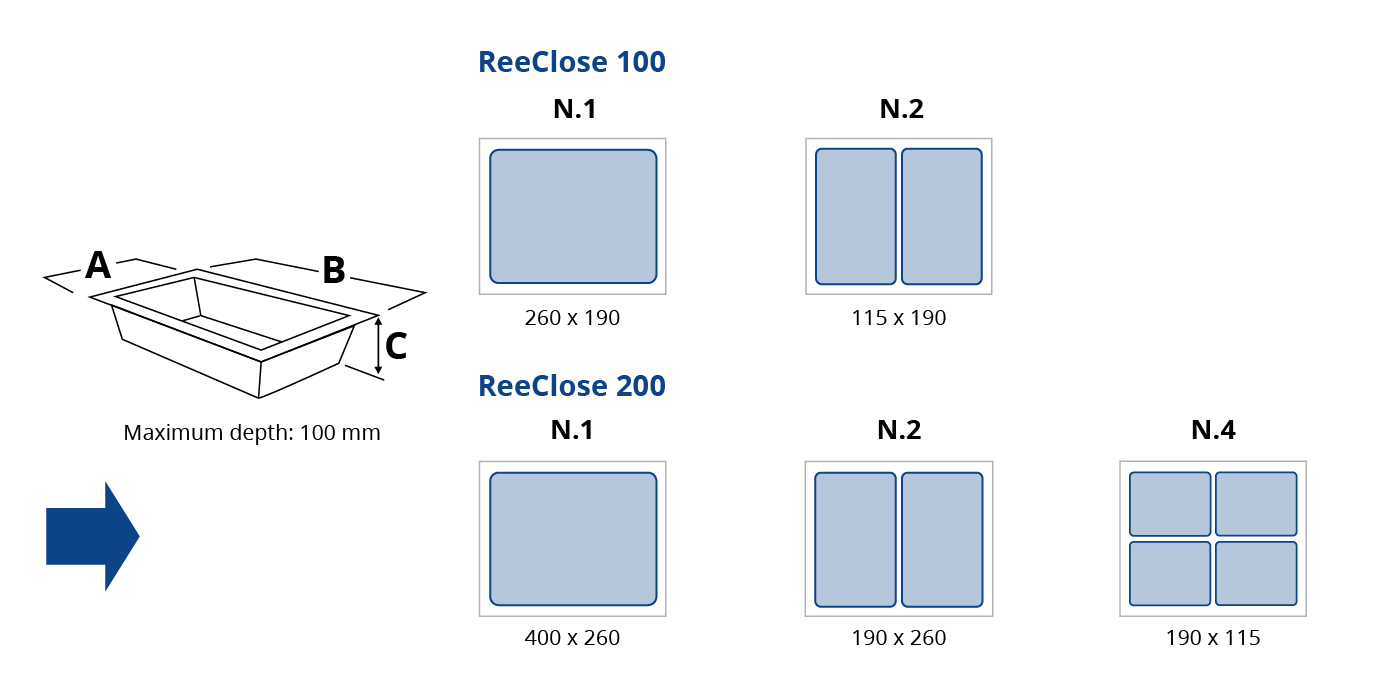

ReeClose 100

High speeds with unique packing flexibility. The ReeClose 100 is a fully automatic, high-performance machine for sealing preformed trays under MAP or closing preformed trays by mechanical process. Compact in size, the technologically advanced ReeClose 100 combines three servo-motors to reach speeds of 8 to 45 cycles/minute. Reeclose lines have the unique flexibility to work with either conventional film seal in MAP or with mechanical CRIMP of aluminum foil or cardboard lids as often demanded by the catering or airline industry. Numerous auxiliary line-equipments will easily integrate into the modular design of the machines.

ReeClose groundbreaking energy efficiency: 0 compressed air consumption in simple seal, only 0.7Nl/c in MAP.

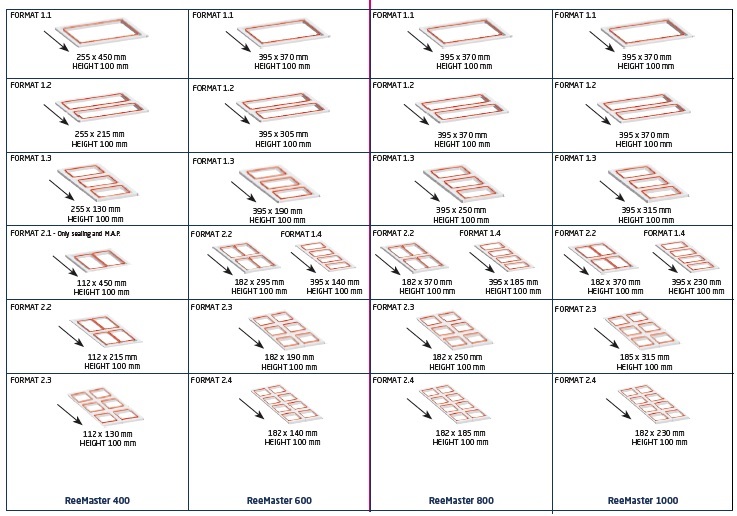

ReeMaster Line

Machines suitable small to large products and large batches. One or two-tracks inline trays can be configurable and a positioning system TPS (Patented Reepack) allows to pack up to 6 trays in two lines. The die is loaded and unloaded by trays with an automatic transfer done by suitable grippers which lock the trays. The grippers movement is precisely defined in HMI and due to the servo motor drive ensure a secure transfer of filled trays. Finally an automatic discharge double belt with differenced speed allows the tray output, in one line at the time, suitable for labelling and weighing.

A wide range of equipment to add in options allow the Reemaster to be easily integrated in a food processing line. The IN-LINE design allows 360° access to all machine components and tooling, allowing easy maintenance and cleaning. Stainless steel wash down construction providing the highest level of sanitization.

Available for M.A.P and Vacuum Skin packages with preformed trays of almost any size, quality or shape.