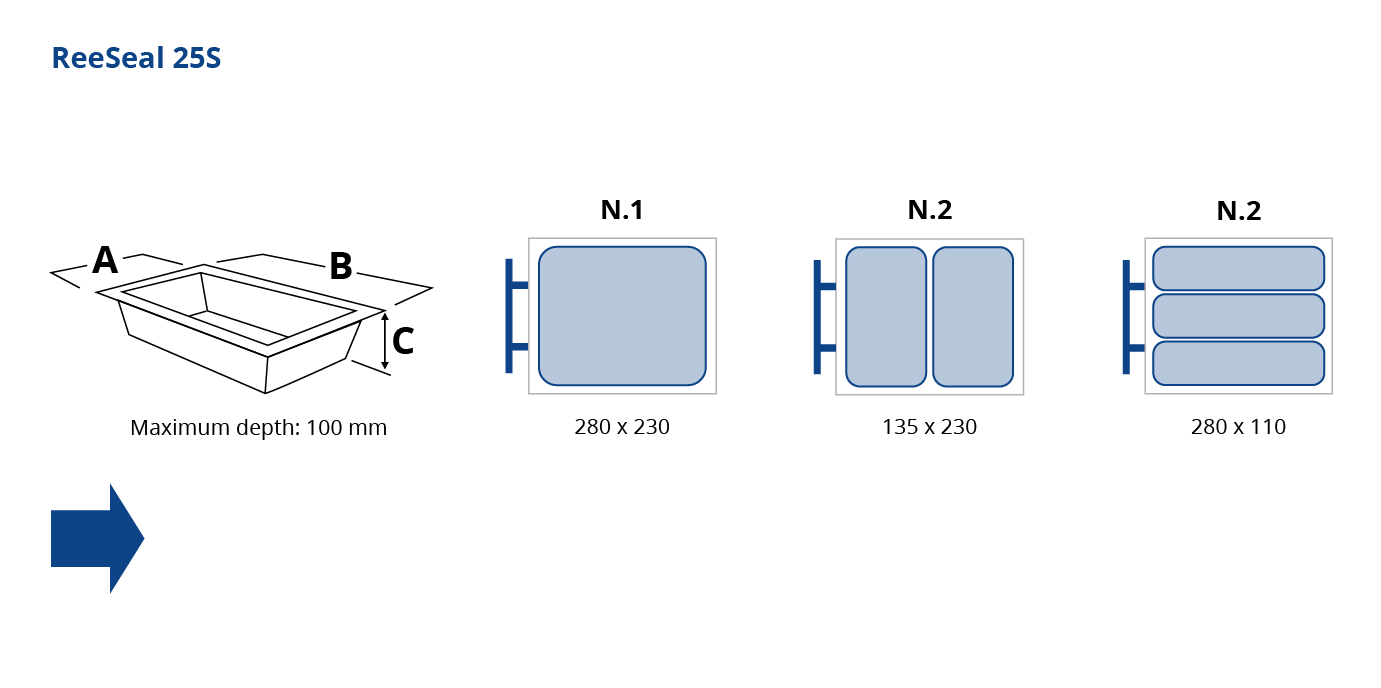

ReeSeal 25

ReeSeal 25 and 32S are tray sealing machines for small packing units such as grocer’s shops, supermarkets, fast food shops, meals on wheels and the like. These machines are equipped with a semi-automatic system providing easy operation, consistent control of sealing parameters, and excellent hermetic seal results. Machine operation requires only a power supply and can be placed in any convenient location. Tool changeover is fast and easy.

The 32SX model has a profile cutting option for clean film trim along the tray’s profile shape. The ReeSeal 32SX die-set can be made compatible for use on ReeTray 20 and ReeBasic machines.

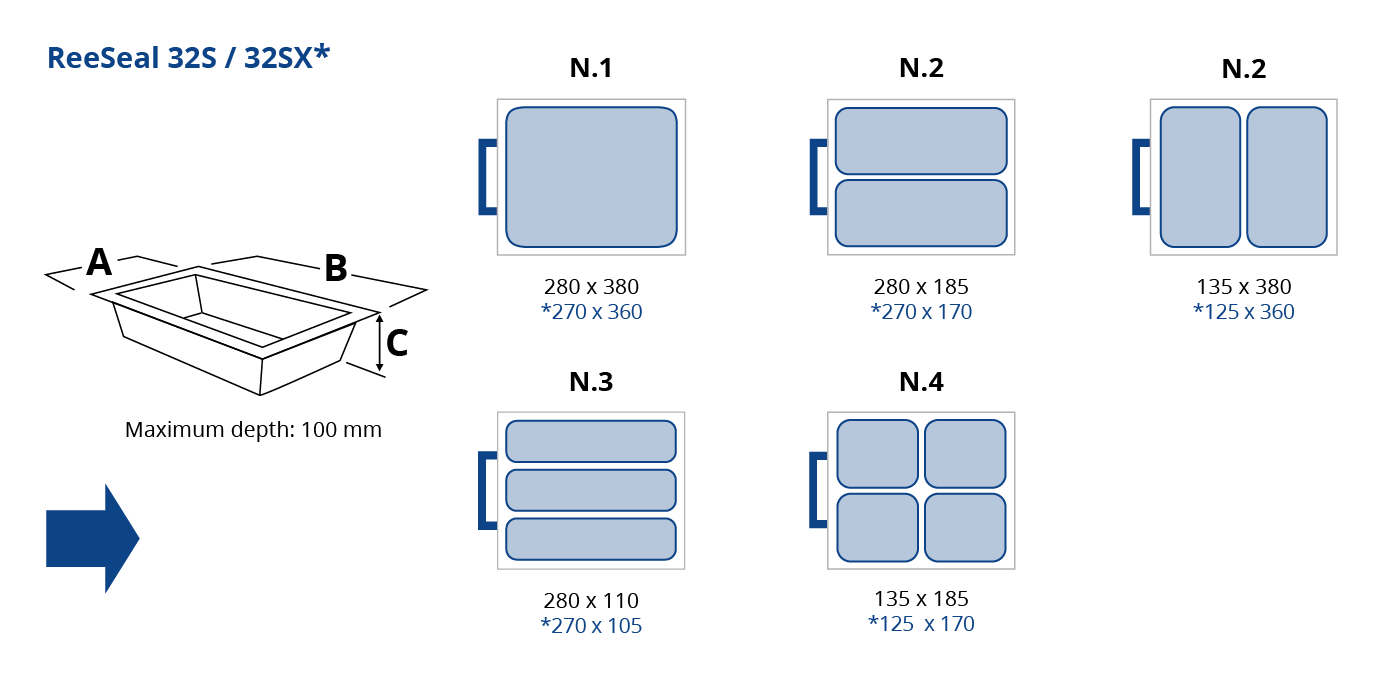

ReeSeal 32S

ReeSeal 25 and 32S are tray sealing machines for small packing units such as grocer’s shops, supermarkets, fast food shops, meals on wheels and the like. These machines are equipped with a semi-automatic system providing easy operation, consistent control of sealing parameters, and excellent hermetic seal results. Machine operation requires only a power supply and can be placed in any convenient location. Tool changeover is fast and easy.

The 32SX model has a profile cutting option for clean film trim along the tray’s profile shape. The ReeSeal 32SX die-set can be made compatible for use on ReeTray 20 and ReeBasic machines.

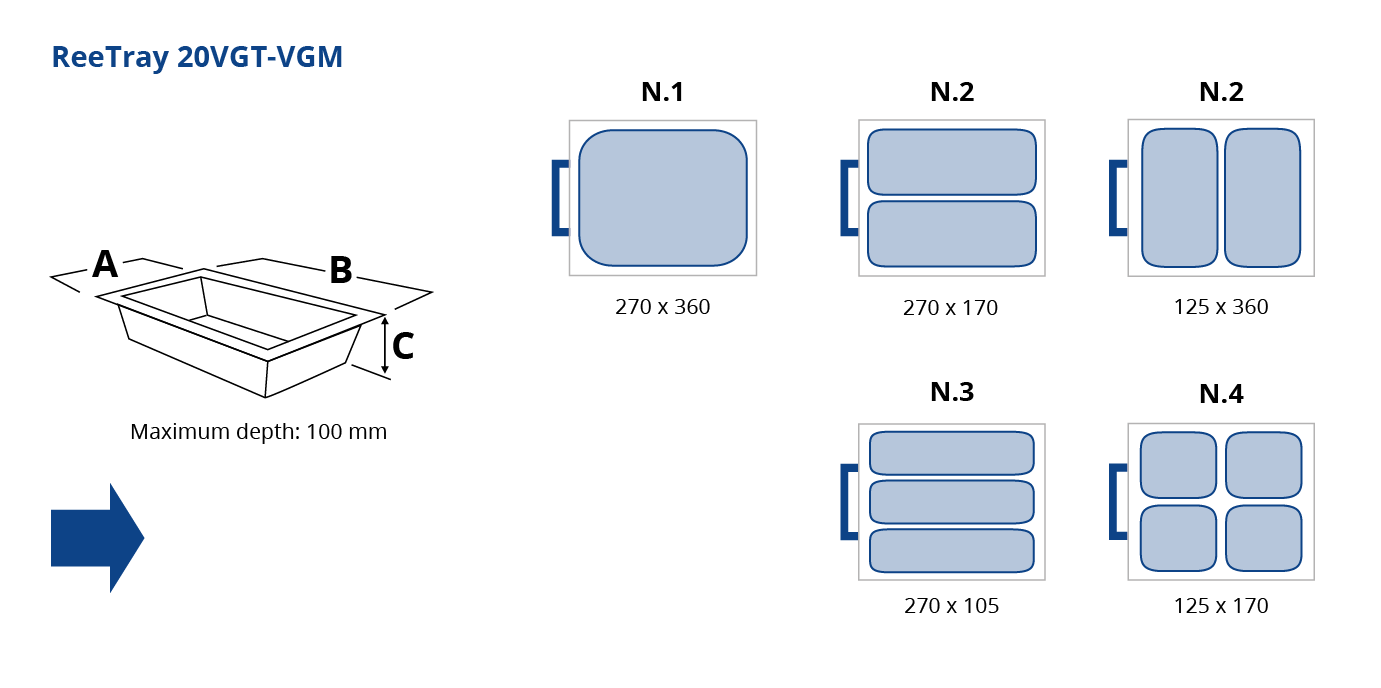

ReeTray 20 VG

The ReeTray 20 can be configured as a table top model (VGT) or with a mobile stand (VGM). Both models are suitable for MAP (Modified Atmosphere Packaging) using Vacuum & Gas operation and can be equipped with different vacuum pump configurations: the “table top” model is available with 20m3/h pump while the “mobile stand” version is available with 20m3/h or 40m3/h pump options. The table top model can be delivered with a stainless steel trolley allowing easier mobility. Tool change over is fast and easy for any operator and a user friendly control panel allows setting and recording different programs for different kinds of products and tray quality.

Thanks to Reepack’s patented system the ReeTray 20 VG requires no compressed air — simply plug and start!

Die-Set compatibility with the ReeBasic fully-automatic model!

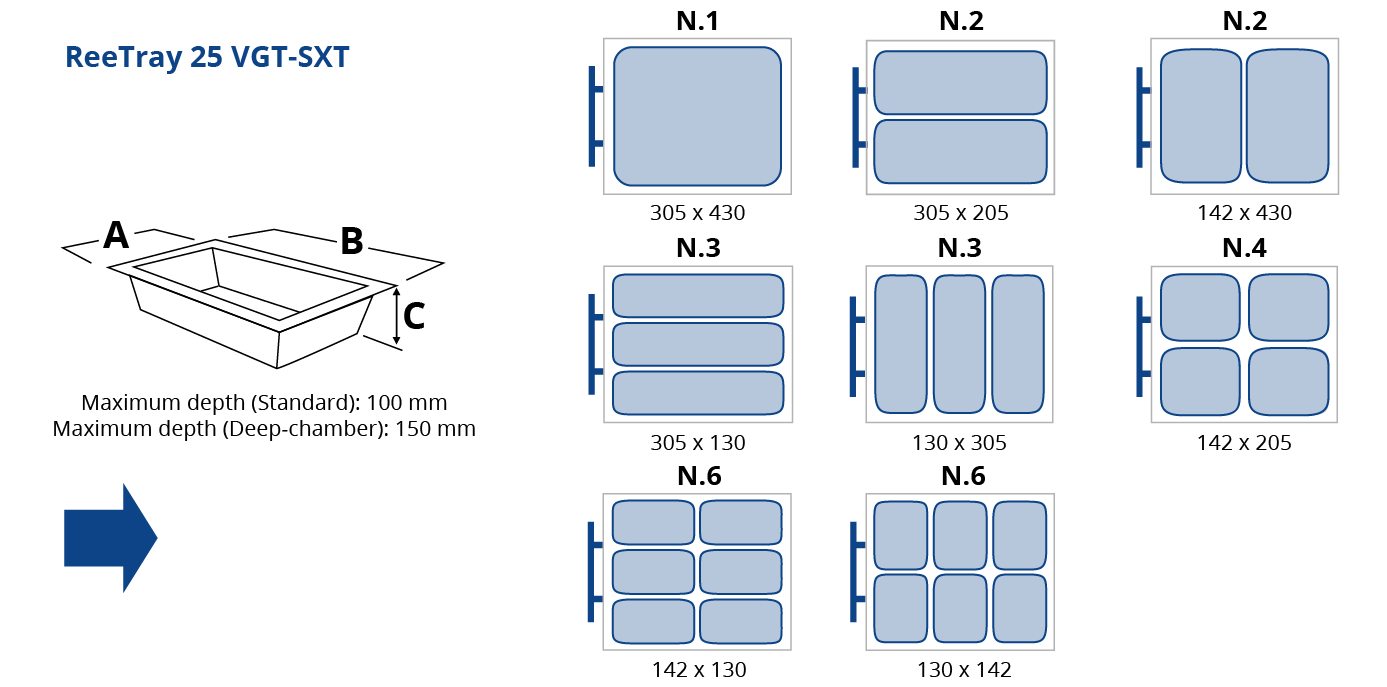

ReeTray 25 VGT or VGM

The most reliable semiautomatic machine on the market, and an ideal choice for MAP (Modified Atmosphere Packaging). Available as table top version (VGT) or mobile version on with wheels (VGM). The ReeTray 25 has heavy duty construction and an extensive range of features and options in a well proven machine. Reliably and effectively able to package MAP, SKIN or GAS-FLUSH this machine brings high performance and flexibility to every working condition including the most aggressive environments: for medium or high production.

Reetray 25-VGM

The optimal MAP semi-automatic machine. Allows to precisely set and control vacuum and gas levels to consistently achieve shelf life objectives with an efficient and reliable heavy duty machine.

RT-25 GAS-FLUSH

The GAS-FLUSH version packs using inert gas without vacuum cycling, resulting in a faster process and approximately 1% residual oxygen ideal for packaging fresh meat or delicate seafood with short shell-life.

RT-25 PAIL

This unique DEEP-CHAMBER version brings to pails or extra deep containers all the features of MAP packaging including the setting and recording of vacuum and gas programs, with overpressure and multi-cycles.

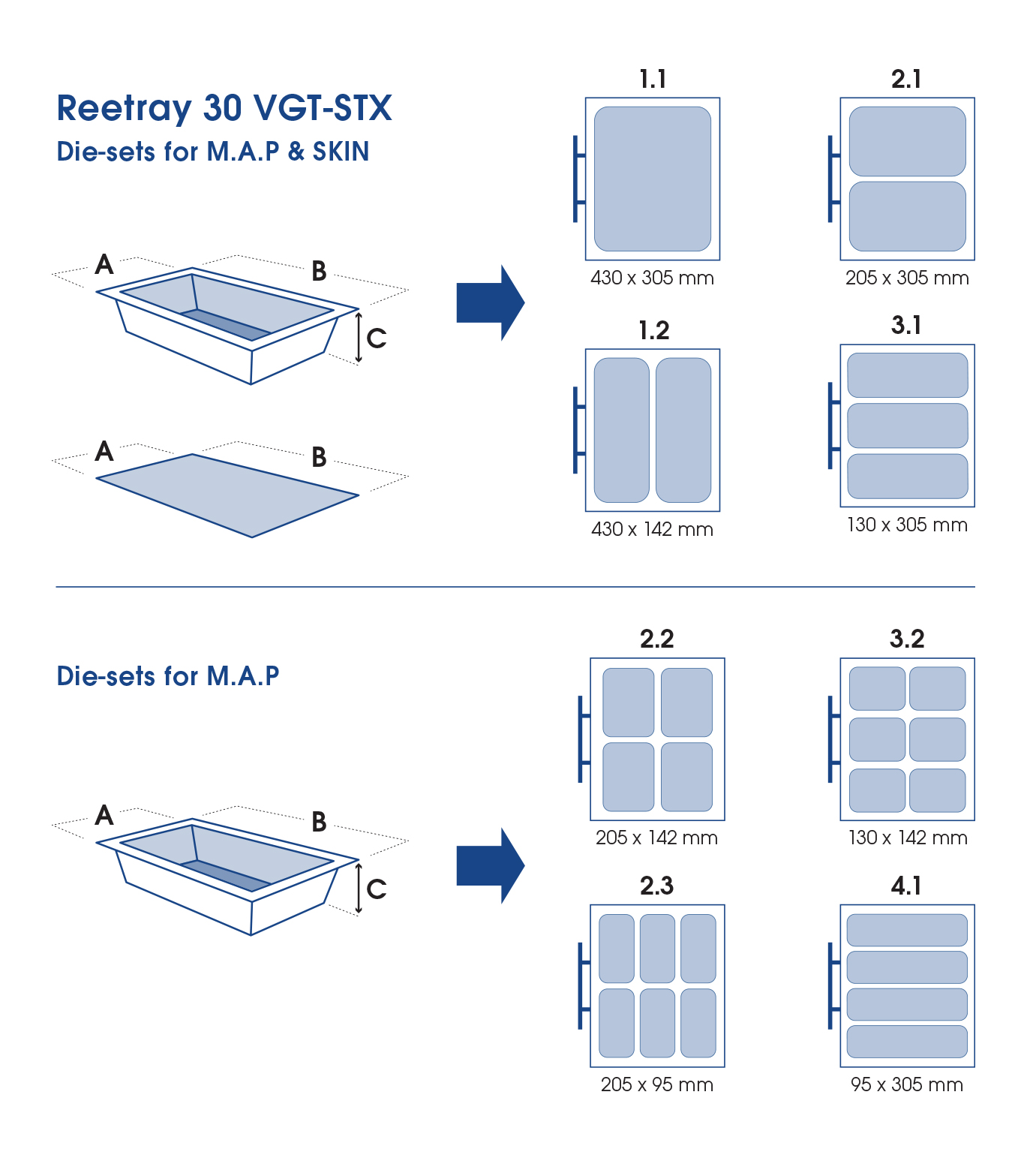

ReeTray 30

Total Vacuum Skin-Pack (VSP) quality in a reliable heavy-duty semi-automatic machine. Specifically designed for flawless VSP performance the RT-30 uses separated upper and lower vacuum chambers with dedicated VSP or MAP die-sets. This machine delivers true uncompromised VSP quality with both standard below tray level and protuberant above tray level applications exceeding tray height by up to 40mm — or even full dimensional products on flat cards. With quick changeover between VSP and MAP tools the RT-30 delivers the rugged durability and flexible performance expected in even the most intensive industrial environments. Suitable for up to high capacity semi-automatic production levels.

One machine for 3 solutions!

Modified Atmosphere Packaging (MAP)

The air is pulled from the packaging and replaced by a specific gas mixture.

Advantages:

- Appetizing product presentation

- Extension of shelf life

- Convenient handling of product

Applications: Meat, fish, cheese, ready meals, vegetables, fruits, bread, pastry.

Vacuum Skin Pack (VSP)

An attractive in rigid-tray vacuum pack that follows the natural shape of the product being packaged like a second skin.

Advantages:

- Excellent Shelf-Life

- Enhanced product visibility

- Attractive presentation

Applications: High quality sliced product, meat cuts, fish cuts, hard cheese.

Protuberant Vacuum Skin Pack (PRO-SKIN-VSP)

Vacuum solution for “protuberant” products up to 100mm total height, with 40mm above tray rim level.

Advantages:

- Excellent Shelf-Life

- Best possible product visibility – 3D effect

- Minimization of packaging

Applications: High quality sliced product, meat cuts, fish cuts, hard cheese.

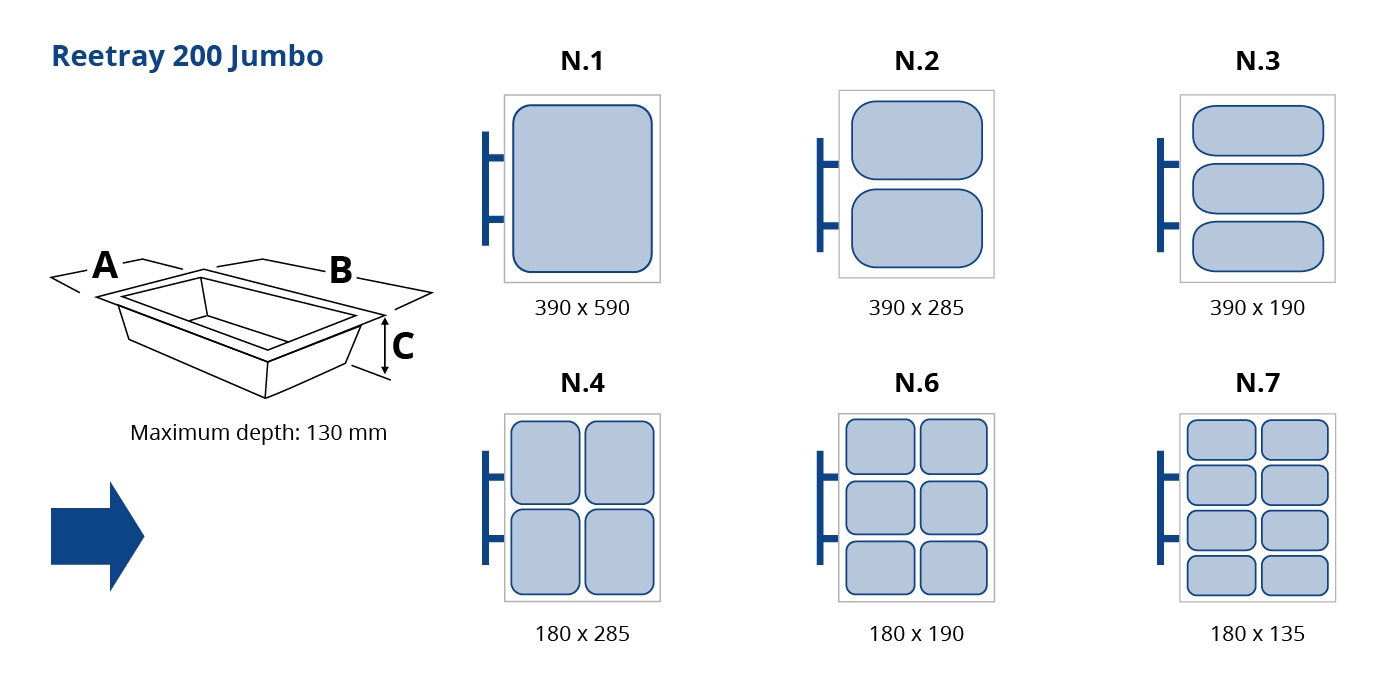

ReeTray 200 Jumbo

The biggest semiautomatic machine in the market, it allows packing extra large containers in MAP. This model seals trays with a maximum dimension of 590 x 390 mm (1 cavity) or 285 x 390 mm (2 cavities). The ReeTray200 Jumbo has a 100m3/h vacuum pump ensuring fast cycles even with large packages. Control panel is user friendly and stores multiple programs. An automatic lifting system enables fluid packed tray transfer onto the machine’s roller exit conveyor. This machine is particularly attractive for meat, fisheries and shipboard use markets.